PUMA Headquarters Lobby

PUMA Lobby “Shoe Prints”. Acrylic. Boston, MA. October 2012

I was approached by PUMA to create some artwork for the lobby of their new headquarters in downtown Boston. In our initial meeting they expressed interest in a branded piece that could be wall mounted or free standing. After measuring the space and taking images, I went to the drawing board. I have worked with the cat in the past and wanted to do something different. After considering many options I proposed enlarged shoe prints on one wall. My concept was to focus not on the PUMA product, but on the trace it left behind.

Detail Shot.

PUMA wrote accompanying labels for the pieces, this is what they said:

“PUMA SUEDE

In 1968, PUMA said ‘nay’ to ordinary leather and the Suede was born. This shoe was worn by athletic greats such as basketball’s Walt ‘Clyde’ Frazier and the track’s Tommie Smith. It later joined b-boy and hip hop crews, and to this day continues to win over feet around the world.

Alessandra Mondolfi, a locally based artist and “Jill of All Trades,” created this acrylic Suede. After inking the real shoe, imprinting, scanning, converting, manipulating, and laser cutting—voilà, folks. An oversized, slick-and-shiny footprint that lives up to the Suede’s smooth rep.”

“TRETORN NYLITE

Since the 1960s, the Nylite has enjoyed nearly every tennis tourney and preppy gathering on record. Made famous by Swedish court legends as much as the world’s Tripps and Bootsies, it’s often reissued with its original terry lining and two-tone colors.

Local artist Alessandra Mondolfi created this oversized Nylite. Her concept focuses not on the shoe, but on the trace it leaves behind: its footprint. It was specially designed to create a large, looming shadow. As large as the Nylite’s legacy? Close.”

Process Images: The “Shoe Prints” started as an analog process. I inked the bottom of the supplied shoes and made hundreds of imprints. From those, 3 were selected of each shoe which I hand colored to further define edges. The hand colored imprints were then scanned, converted into vector files and further manipulated to simplify and stylize the smudged quality of the shoe print. The files were enlarged to fit into a 4’x8’ sheet of material. I choose black acrylic to contrast the white wall and to achieve the reflective quality of the final piece in which the viewer can see him or herself and the surrounding space. I laser cut the pieces out of ½” acrylic and experimented with ways to keep all of the pieces together for transport and installation. I wanted the final pieces to float off of the wall so that it would cast shadows. To achieve this I strategically adhered nails to the back of the piece that would later be pressed into the drywall. On site, once location and position were determined we placed the piece, affixed it to the wall and took off the protective film to reveal the surface. Lighting was adjusted to play with the shadows and bring forward the logos.

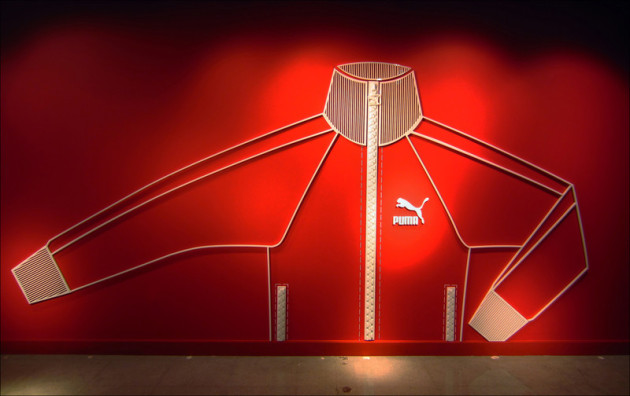

PUMA Lobby “Jacket”. Acrylic. Boston, MA October 2012

On the opposite wall, I made a jacket.

And this was the text they wrote for it’s label:

“PUMA T7 TRACK JACKET

Known for its tapered 7 centimeter stripe, the T7 Track Jacket debuted in 1968 and was donned by track stars and football greats. More recently, it has graced Motown press shoots and hip hop album covers…

And this wall. Created by

local artist Alessandra Mondolfi, it was conceived from a line drawing of the jacket. With extreme attention to detail – cuffs, zips, collar, stripe, and all – she laser cut the design out of acrylic

and installed it here. Just for you.”

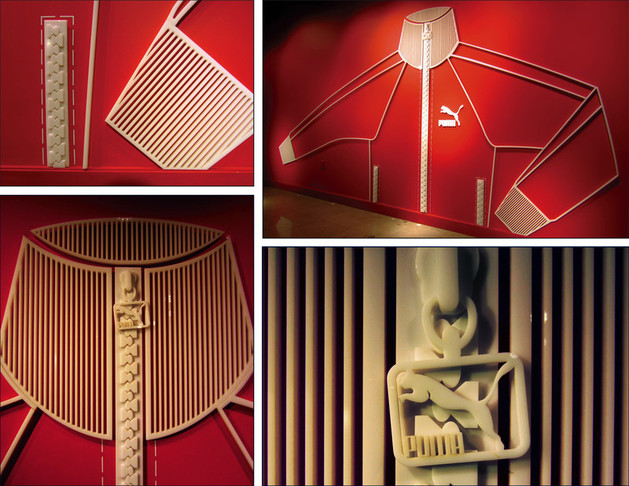

Above: Detail shots.

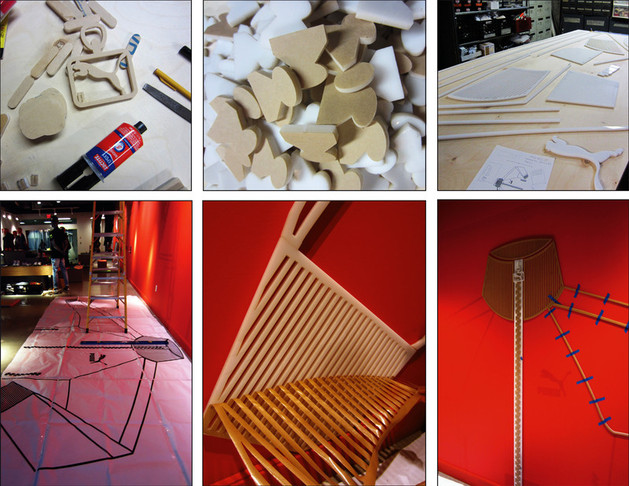

The “Jacket” although made of the same material, was a very different process. It was conceived from the supplied line drawing of the jacket. I broke the line drawing into pieces, gave them a visual thickness, altered the cuffs and collars with the intention of making them look ribbed and focused my attention on the zipper and zipper pull. The zipper was made by layering laser cut pieces of ¼” white acrylic and the rest of the jacket was laser cut out of ½” white acrylic. The same method of adhered nails was used for installation.

Bellow: Process images.